- Other Gears[10]

- Ring Gears[10]

- Pinion Gears[2]

- Medical Rubber[10]

- Automotive Plastic Products[10]

- Other Electronic Components[7]

- Home Appliance Plastic[1]

- Other Power Transmission Parts[1]

- Electronic Plastic[10]

- Other Auto Parts[9]

- Integrated Circuits[1]

- Electrical Contacts and Contact Materials[2]

- Computer Cables & Connectors[5]

- Connectors[3]

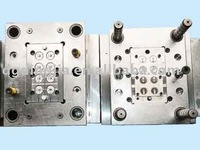

- Moulds[10]

- Other Machinery[1]

- Contact Person : Ms. tang judy

- Company Name : Dongguan Dingjia Precision Mold Co., Ltd.

- Tel : 86-769-85090986

- Fax : 86-769-85090989

- Address : Guangdong,dongguan,B9 conrad hi-tech park shangsha sectioin of ZhenAn Road, Chang An Town, Dongguan city, guangdong province

- Country/Region : China

plastic mould for connector

plastic mould for connector

1. High-precison and good quality

2. Competitive price and on-time delivery

3. High quality mould base from LKM,DME,HASCO

4. ISO 9001:2008 certified

5. Long lifespan

6. 3D design service.

7. OEM/ODM service.

8. Excellent after-sale service.

We are a manufacturer engaged in research ,production and distribution of various moulds and automatic control equipments as well as injection mould processing and plastic products.The main line of our business includes Computer connectors ,Office communication series ,SMD series mould and Component processing ,SMD automatic feed-in system,High-speed PIN system and Plastic cog coupling system..

A good design is the heart of a mould ,therefore the engineers here all have academic credentials about four yours” education and abundant practical experience .With the skillful engineers and internationally advanced CAD/CAM/CAE software system ,your 3D drawings or sample will turn to be the perfect product you have expected.

If you are interested in ,please contact me ,we are always at your service.Thanks!

Name | Description |

Mould material | 45#, 50#, P20, H13, 718, 2738, NAK80, S136, SKD61 etc. |

Mould base | LKM, HASCO,S136 ect |

Cavity | Single/multi |

Runner | Hot/cold |

Design software | UG, PROE, CAD, CAXA ect. |

Plastic material | PP, PC, PS, PE, PU, PVC, ABS, PMMA ect. |

Mould life | 300,000-3,000,000 shots |

Delivery time | 15-60days |

Specification | Depends on customer's requirements. |

Step

| ||||||||||||||||||||||||||

plastic mould for connector